Technological Process And Key Points Of Peanut Butter

Peanut is a kind of food that many people like to eat. In addition to its unique flavor, organization and taste, it also contains many kinds of nutrients needed by human body. Therefore, peanut butter is one of the most widely processed foods in the market.

Here for you to explain, peanut butter process and production points.

Brief technological process: peanuts baking → cooling → removing red coat and germ → rough grinding → fine grinding → degassing → cooling → packaging

The technological process of making peanut butter is: peanut kernel → baking → cooling → peeling → sieving → picking rotten kernel → primary grinding sauce → fine grinding sauce → homogenization → canning → freezing → room temperature preservation.

Key points of production:

Baking: heat the peanut to 160 ℃ and keep it for 40-60 minutes. The color inside and outside of the peanut kernel shall be the same without burning.

Cooling and sieving: after roasting, the peanut kernel is quickly discharged, spread and air cooled as soon as possible, and then peeled with a peeler after cooling. After sieving, the cotyledon and germ are separated.

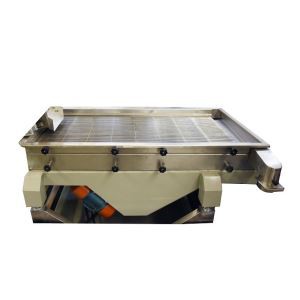

Grinding sauce: put the separated cotyledons into the grinding for grinding sauce, the first coarse grinding, grinding into medium fineness, the second fine grinding, grinding into fine and smooth finished products. Add sugar or salt (2% - 3% sugar, 0.5% salt) and 0.05% vitamin E in the second grinding.

Homogenization: heat peanut butter to 60-70 ℃ in a mixing tank, add 2% monoglyceride and 1-5% soybean protein powder, mix evenly.

Canning and freezing: put peanut butter into the jar and freeze it at a low temperature of about 0 ℃.

After the whole crystallization is completed, it can be moved. After that, it can be stored at room temperature.